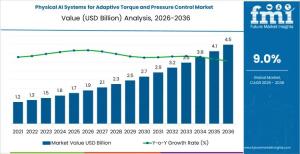

demand for physical AI torque and pressure control systems is forecast to grow USD 4.5 billion by 2036

Global demand is projected to grow from USD 1.9 billion in 2026 to USD 4.5 billion by 2036 as manufacturers adopt real-time adaptive force control.

NEWARK, DE, UNITED STATES, January 19, 2026 /EINPresswire.com/ -- Global manufacturers across robotics, precision assembly, and medical automation are accelerating adoption of physical AI systems that adapt torque and pressure in real time. According to the latest demand outlook updated January 17, 2026, worldwide demand for these systems is estimated at USD 1.9 billion in 2026 and is forecast to reach USD 4.5 billion by 2036, reflecting a compound annual growth rate (CAGR) of 9.0%.

Growth is occurring across Asia Pacific, Europe, North America, Latin America, and the Middle East & Africa, with the fastest expansion in China and South Korea. The demand is being driven by operational needs for higher precision, safety compliance, and quality consistency in contact-rich industrial processes, and is being met through hybrid upgrades that layer adaptive control software and sensing onto existing automation infrastructure.

Request For Sample Report | Customize Report |purchase Full Report - https://www.futuremarketinsights.com/reports/sample/rep-gb-31508

Market Context: From Pilot Projects to Structured Capital Spending

Demand for physical AI systems that dynamically adjust torque and pressure is shifting from isolated trials into planned, application-led spending. Buyers are prioritizing operations where fixed settings fail under part variation, changing materials, or tool wear, including precision assembly, fastening, press fitting, dispensing, finishing, and controlled clamping. Near-term investments focus on higher-fidelity force and pressure sensors, tighter closed-loop control at the edge, and software capable of learning acceptable force profiles and detecting drift early.

Market Statistics

• Demand Value (2026): USD 1.9 billion

• Forecast Demand Value (2036): USD 4.5 billion

• Forecast CAGR (2026–2036): 9.0%

• Leading Technology Type: Reinforcement learning control systems (42.0% share)

• Fastest-Growing Applications: Collaborative robotics, surgical automation, precision assembly

• Key Companies Active in Demand: NVIDIA Corporation, Siemens AG, ABB Ltd., Honeywell International Inc., Boston Dynamics, Inc.

Enterprise Spending Patterns: Phased, Application-Led Investments

Over the next one to two years, enterprise spending is expected to remain phased and station-specific. Most budgets will flow to torque- or pressure-critical steps where contact quality directly affects scrap, rework, operator safety, or equipment life. Typical procurement bundles hardware, integration, commissioning, and verification services, reflecting the need to tune adaptive systems to defined force and pressure envelopes.

Operating budgets are also rising alongside capital expenditures. Buyers are allocating funds for monitoring, calibration routines, spares, remote support, and performance reporting to control drift. Safety and governance spending is increasing in parallel, driven by collaborative operation guidance and functional safety practices. Standards and measurement frameworks referenced by ISO, IEC, and NIST are influencing buying behavior, pushing manufacturers to pay for traceability and documented validation, not only for robots or actuators.

Technology Segmentation: Reinforcement Learning Leads Adoption

Reinforcement learning control systems account for 42.0% of total demand, driven by their ability to learn optimal control policies through trial-and-error interaction with physical processes. Computer vision-based force control holds 28.0%, enabling visual feedback for component positioning and surface contact monitoring. Neural network pressure controllers represent 18.0%, favored for modeling non-linear pressure-flow relationships in hydraulic and pneumatic systems. Sensor fusion algorithms contribute 8.0%, integrating multiple data streams for comprehensive force and pressure monitoring, while other AI control technologies account for 4.0%.

Control Functions: Real-Time Adaptation and Predictive Maintenance

By control function, real-time force adaptation represents 35.0% of demand, reflecting priority on dynamic torque and pressure adjustment during operations. Predictive maintenance and monitoring account for 27.0%, supporting equipment protection and operational continuity. Safety and collision avoidance hold 22.0%, enabling human-robot collaboration in shared workspaces. Process optimization and efficiency represent 16.0%, addressing productivity targets through intelligent control algorithms.

Applications Driving Demand Growth

Collaborative robotics and automation lead with a 32.0% share, requiring sophisticated force control for safe human-robot interaction and precision tasks. Precision manufacturing accounts for 26.0%, applying adaptive control to material handling, component insertion, and quality assurance. Medical devices and surgical robotics represent 18.0%, relying on precise pressure control for patient safety. Process industries and chemical processing hold 14.0%, while research and development accounts for 10.0%, where experimental control architectures drive innovation.

Global Outlook: Asia Pacific Leads, Regulated Markets Sustain Demand

China is forecast to grow at a 10.2% CAGR, driven by electronics assembly, automotive manufacturing, and export-oriented precision production. South Korea follows at 9.4%, supported by semiconductor manufacturing and robotics development. The United States is projected to grow at 8.7%, with demand concentrated in aerospace, medical devices, and collaborative robotics. Germany is forecast at 7.9%, influenced by Industry 4.0 initiatives and automotive automation. Japan is projected at 7.1%, with demand centered on high-precision and long-term reliability applications.

Across all regions, adoption remains driven by control performance requirements and safety standards rather than automation volume expansion alone. Growth reflects the rising integration of intelligent control systems, edge computing platforms, and real-time learning algorithms across manufacturing and medical automation.

Competitive Landscape and Industry Structure

The competitive ecosystem includes major robotics OEMs such as ABB, FANUC, KUKA, Yaskawa, and Universal Robots; automation leaders including Siemens, Rockwell Automation, and Schneider Electric; and sensor specialists such as Sick and Keyence. System integrators play a central role in deploying and validating adaptive control systems within production lines. Standards bodies, including ISO/TC 299 and national metrology laboratories, continue to shape safety and performance benchmarks.

Outlook Through 2036

Demand for physical AI systems for adaptive torque and pressure control is expected to remain disciplined and application-led. Adoption will continue to be gated by qualification milestones, operational integration. Acceleration is anticipated once internal specifications, acceptance tests, and reusable parameter sets are standardized, enabling replication across lines and sites. As manufacturers prioritize auditable force, adaptive control is positioned to become a foundational capability in collaborative robotics, precision manufacturing, and surgical automation through 2036.

Browse Related Insights

Compost Turning Machine Market Share Analysis: https://www.futuremarketinsights.com/reports/compost-turning-machine-market-share-analysis

Mini Cranes Market Share Analysis: https://www.futuremarketinsights.com/reports/mini-cranes-market-share-analysis

Power Amplifiers Market Share Analysis: https://www.futuremarketinsights.com/reports/power-amplifiers-market-share-analysis

About Future Market Insights (FMI)

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.